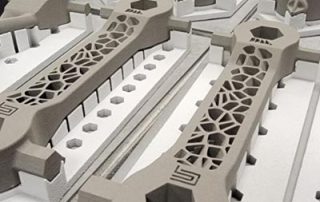

New Formlabs Form 3 Plus 3D Printer

Today we are going to take a look at the new Formlabs Form 3+ and the Build Platform 2. The best-selling professional SLA 3D printer just got better with game-changing print speed, surface quality, and reliability. We will break down the Form 3+ improvements into two segments - Hardware & Software, both of which significantly improve print speed. Hardware Updates With an improved thermal system, enhanced LPU stability, and an optimized laser your print times [...]