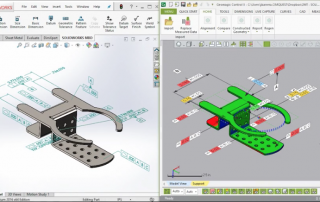

Find Level from Geometry- Mastercam 2019

https://cimquesttv.wistia.com/medias/zdeu04da4p?embedType=iframe&videoFoam=true&videoWidth=640 Find Level from Geometry In this underrated feature, we can quickly find which levels our geometry is assigned to rather than manually turning each level on and off until we find the one we want to manipulate.