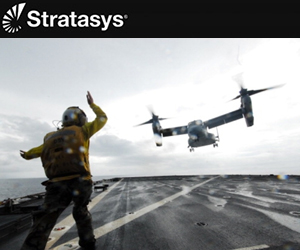

The Navy has been using 3D printed parts on the Osprey tilt-rotor craft and plans to expand the uses of the technology. (Photo : Allen Onstott / U.S. Navy via Getty Images)

The U.S. Navy explored fleet applications of additive manufacturing, or 3D printing, into naval weapons systems at the 2015 Naval Additive Manufacturing Technical Interchange (NAMTI) meeting at the Carderock Division of the Naval Surface Warfare Center. Hundreds of engineers, scientists, acquisition professionals and 3D printing experts, discussed naval applications of additive manufacturing for bio-printing, self-sustaining ships and energetics, such as military weapons.

The U.S. Navy reports five ways it has used 3D printing technology successfully:

- Save money and time. Norfolk Naval Shipyard’s Rapid Prototype Lab is saving the Navy thousands of dollars by printing cheaper plastic polymer models of aircraft carrier ship alterations in hours, rather than days or weeks for traditional wood or metal mockups.

- Innovative. The Navy’s Fleet Readiness Center Southeast used the technology to develop an improved hydraulic intake manifold for the V-22 Osprey. The new manifold is 70 percent lighter, improves fluid flow and has less leak points.

- Customizable. By customizing 3D printed parts, the Walter Reed National Military Medical Center produces medical items, including tailor-made cranial plate implants, surgical guides and medical tooling.

- Overcoming obsolescence. Naval Undersea Warfare Center-Keyport used additive manufacturing to create a supply of replacement circuit card clips for J-6000 Tactical Support System Servers onboard nuclear-powered guided-missile submarines to keep the Fleet ready.

- Increase fleet readiness. A 3D printer was installed by the Chief of Naval Operations aboard the USS Essex this year. The 3D printer developed and printed several shipboard items, like oil reservoir caps and deck drain, as well as tools and training aid covers.

Watch the short video below to see how the Navy is utilizing 3D printing capabilities.

Leave A Comment