In the News

Desktop Metal Expands 3D Printing Lineup

August 30, 2022

Desktop Metal Expands Lineup for World’s Best-Selling Metal Binder Jet System with Shop System+ and Shop System Pro

Desktop Metal announced two upgrade packages on its Shop System™, offering new flexibility, functionality, and value for the world’s best-selling metal binder jet system. The Shop System+ and Shop System Pro offer power users new options for materials and controls. (Photo: Business Wire)

First unveiled in November 2019, the Shop System was designed to bring metal additive manufacturing to machine and job shops with an affordable, turnkey solution that achieves exceptional surface finish parts with rich feature detail at speeds up to 10 times those of legacy powder bed fusion additive technologies.

To date, Shop System users worldwide have logged more than 20,000 print hours. Now, Desktop Metal is expanding the lineup of this successful platform with the Shop System+ and the Shop System Pro, giving power users more flexibility and control over operating costs and machine parameters. The Shop System+ package enables high-production users to access Desktop Metal-engineered powders and binders at a discount, reducing the running costs of operations and improving part costs to drive a faster return on investment. The Shop System Pro package is ideal for high-production users with powder metallurgy expertise who seek not only to optimize running costs but also enable specific applications or cost structures by leveraging proprietary or third-party powders with additional process flexibility through custom printing and spreading parameters and bi-directional printing, as well as custom sintering profiles for the Desktop Metal Furnace.

“Customers love the affordability, quality, and reliability of the Shop System, and the Desktop Metal team is excited to expand on this successful platform,” said Ric Fulop, Founder and CEO of Desktop Metal. “The Shop System has become a global success, and we’ve really taken a sinter-based production process that used to require specialized knowledge and made it accessible on many levels. In addition to being affordable, our software and controlled powder and binder supply chain have made 3D printing metal parts easy and reliable.”

Shop System Details

Featuring the highest resolution and most advanced single pass print engine in the binder jetting market, the Shop System is a complete end-to-end solution for producing complex, end-use metal parts that includes:

- a binder jetting printer with 1600 native dpi resolution and 5x nozzle redundancy,

- a drying oven for hardening green parts prior to depowdering,

- a powder station for depowdering parts with built-in powder recycling,

- a furnace designed for accessible, industrial-strength sintering,

- integrated powder handling accessories and workflow,

- Desktop Metal-engineered binders and powders, and

- Desktop Metal software for build preparation and sintering simulation.

This turnkey solution, designed with the modern machine shop in mind, seamlessly integrates with existing shop operations and makes it easy for businesses to get up and running with binder jetting in days instead of weeks or months.

Desktop Metal Upgrades Live Sinter™ Software

August 30, 2022

Desktop Metal Announces Upgrades to its Popular Live Sinter™ Software, a Powerful Multi-Physics Simulation Tool that Delivers Trusted Results

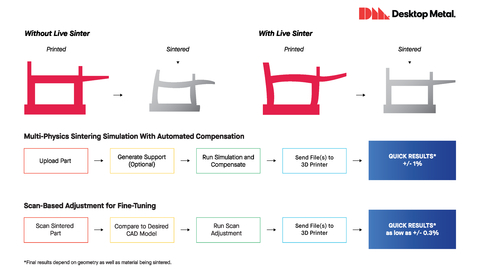

Live Sinter simulation software predicts and corrects for shrinkage and distortion in metal parts 3D printed with binder jetting technology. Sinter-ready, printable geometries are provided in as little as 20 minutes and deliver highly accurate final part results. (Graphic: Business Wire)

Desktop Metal, Inc. (NYSE: DM), a global leader in additive manufacturing technologies for mass production, today announced significant updates to Live Sinter — a powerful multi-physics sinter simulation software application that automates the generation of sinter-ready, printable geometries, as well as supports, setters, and inserts, to make repeatable, volume production of high-precision end-use metal parts through binder jetting more accessible.

Launched in the fall of 2020, Live Sinter is now trusted by users at more than a hundred companies globally, and the software is a key enabler of Desktop Metal’s AM 2.0 binder jetting solutions, making them easier to adopt and ramp to production for customers without any prior powder metallurgy or sintering expertise.

Live Sinter’s powerful multi-physics simulation and compensation software delivers sinter-ready, printable geometries that maintain tight shape and dimensional tolerances. After scan-based adjustments, Live Sinter enables correcting for complex distortion effects, yielding parts that consistently fall well within 1% of target dimension with as low as +/- 0.3% deviation, avoiding distortion, warping, and other common sintering challenges, as well as the cost and time associated with supports or setters.

“Within the field of sinter-based additive manufacturing, Live Sinter stands alone for its ease of use and functionality,” said Ric Fulop, Founder and CEO of Desktop Metal. “No other solution offered today combines our powerful, rapid multi-physics simulation with scan-based adjustments and automated support and setter generation. Customers continue to report their absolute delight with this tool to us, and we look forward to continuing to invest in advancing Live Sinter to make sinter-based manufacturing accessible to an ever wider audience, including metal injection molding customers.”

A Key to Metal Printing Success

Live Sinter is a critical companion to Desktop Metal’s portfolio of metal binder jetting systems, which produce parts that must be sintered in a furnace to fuse the particles into a high-density material.

Desktop Metal offers the broadest portfolio of metal binder jetting systems, including the Shop System, X-Series and Production System P-1 and P-50. Several of these systems include Desktop Metal’s furnace, which simplifies and reduces costs associated with the sintering process across a range of geometries and materials for businesses new to binder jetting. The Company’s printers support processing 30 metals across volume production, specific customer applications, or research and development. Learn more at https://www.desktopmetal.com/materials.

The Shop System is now the world’s best-selling metal binder jet printer, and Live Sinter has been a critical component of that turnkey printer’s ease of use and success.

“One of my biggest worries investing in this technology was the furnace and the frustration of failing that far into the process during sintering. Using Live Sinter, I’m blown away at our success with the sintering furnace,” said Neil Glazebrook, Vice President of 3D Solutions at ABCorp in Boston. His company invested in a Shop System and Desktop Metal Furnace in 2021 for the production of 17-4PH stainless steel parts. The company had no prior sintering experience. “I don’t have to use sintering supports anymore, so I don’t have to charge for supports. I use Live Sinter for everything, and it makes it more competitive.”

“We’ve found Live Sinter to be an extremely valuable tool for FreeFORM. The ability to print, scan, adjust, reprint, etcetera, has reduced our lead time by helping us yield product in spec faster than a traditional trial and error loop. The ability of the software to predictively deform products prior to first manufacturing or to take first-off parts and make adjustments have resulted in our customers getting to market faster with product so they can move on to their next development,” said Chris Aiello, Co-Founder, FreeFORM Technologies of St. Marys, Pennsylvania. FreeFORM owns three Shop System printers, as well as a Production System P-1 and an InnoventX.

Sean Harkins, President, AmPd Labs, in Houston, Texas, owns a Shop System and says Live Sinter is an essential part of his company’s success with it. “We use it all the time now, and it’s a dramatic change. We simulate, print, scan and reprint and it comes out perfect,” he said.

To learn more about Live Sinter, visit https://www.desktopmetal.com/products/livesinter

About Desktop Metal

Desktop Metal, Inc., based in Burlington, Massachusetts, is accelerating the transformation of manufacturing with an expansive portfolio of 3D printing solutions, from rapid prototyping to mass production. Founded in 2015 by leaders in advanced manufacturing, metallurgy, and robotics, the company is addressing the unmet challenges of speed, cost, and quality to make additive manufacturing an essential tool for engineers and manufacturers around the world. Desktop Metal was selected as one of the world’s 30 most promising Technology Pioneers by the World Economic Forum and named to MIT Technology Review’s list of 50 Smartest Companies. For more information, visit www.desktopmetal.com.

MakerBot and Ultimaker Merger Will Accelerate Global Adoption of Additive Manufacturing

May 13, 2022

MakerBot and Ultimaker, two leaders in desktop 3D printing, today announced that they have come to a business combination agreement that will accelerate the adoption of additive manufacturing by providing a comprehensive desktop 3D printing ecosystem of hardware, software, and materials.

The new entity will be backed by existing investors, NPM Capital and Stratasys (Nasdaq: SSYS), and will benefit from a planned cash investment of $62.4 million to fuel innovation and expansion into new markets. The new company will be led by Nadav Goshen, current MakerBot CEO, and Jürgen von Hollen, current Ultimaker CEO, who will act as Co-CEOs, with Nadav managing operations and R&D and Jürgen managing the commercial functions.

“This merger marks an important milestone for Ultimaker and MakerBot,” says Jürgen von Hollen, CEO of Ultimaker. “Innovation and growth are both critical to bringing desktop 3D printing from a specialty technology into mainstream business adoption. The new company will leverage and expand its combined global footprint with sales and operations in the Americas, EMEA and APAC.”

“Technological innovation is paramount in growing the availability of easy-to-use professional 3D printing solutions,” says Nadav Goshen, CEO of MakerBot. “By combining our teams and leveraging the additional funding, we can accelerate the development of advanced solutions to provide our customers with a broad portfolio of hardware and software solutions to serve a wide spectrum of customers and applications.

The new entity aims to offer easy-to-use and accessible desktop 3D printing solutions for any application while inspiring the industry to a future state of responsible and sustainable manufacturing.

The new company will maintain headquarters in both The Netherlands and New York, USA.

The transaction is subject to consultation of appropriate employee representative bodies and regulatory approvals, with closing currently expected over the course of the second or third quarters of 2022.

About MakerBot

MakerBot is a global leader in the desktop 3D printing industry. MakerBot empowers the engineers of today and tomorrow with its powerful additive manufacturing ecosystem. The company strives to redefine the standards for 3D printing for safety and emissions, reliability, accessibility, precision, and ease-of-use. Through this dedication, MakerBot has a large install base, manages Thingiverse—the largest 3D printing community in the world—and has members on the UL 2904 standards committee to ensure it is on the cutting edge of emissions regulations.

About Ultimaker

Established in 2011, Ultimaker is on a mission to accelerate the world’s transformation to flexible, empowering and sustainable solutions. 380 employees deliver a platform that enables customers to take full advantage of the unique Ultimaker Ecosystem that offers the largest diversity of 3D printing products and services in the industry. Ultimaker provides a seamless integration of hardware, software and materials that simply works.

Cimquest expands their 3D Printing Portfolio with Ultimaker

Branchburg, NJ USA September 14, 2020

Today Cimquest, Inc. announced their partnership with Ultimaker to provide professional 3D printers, software, and materials in the New England and Mid-Atlantic region.

Cimquest is a leading resource for CAD/CAM, 3D Printing, and Reverse Engineering solutions and they were looking at how to further support their customer base. “We realized our customers were seeking an open material platform for 3D printing that was easy-to-use and enterprise ready. Frankly, Ultimaker was the perfect fit,” said Shawn Crews, President of Cimquest.

Along with the Enterprise Cura software and expanded Ultimaker S line, Cimquest also plans to utilize their application engineers to assist customers with the most demanding customer applications. “Cimquest saw a great opportunity to bring on a value brand to fill out their product portfolio,” said Greg Elfering, President of Ultimaker Americas at Ultimaker. “With the growing demand of Ultimaker, we are excited to have a great partnership with a highly respected reseller and engineering team in the northeastern US.”

About Ultimaker

Since 2011, Ultimaker has built an open and easy-to-use solution of 3D printers, software and materials that enable professional designers and engineers to innovate every day. Today, Ultimaker is the market leader in desktop 3D printing. From offices in the Netherlands, New York, Boston, and Singapore – plus production facilities in Europa and the US – its global team of over 400 employees work together to accelerate the world’s transition to digital distribution and local manufacturing.

More information on the company is available at www.ultimaker.com.

Xactly what we needed to democratize Laser Powder Bed Metal Printing

Branchburg, NJ USA September 10, 2020

Cimquest has teamed up with the State College, Pennsylvania-based Xact Metal to bring their low entry cost and small footprint, laser powder bed fusion metal 3D printer to budding enterprise shops and manufacturers without sacrificing quality or accuracy.

For a number of years, Metal Laser Powder Bed Fusion technologies have been somewhat out of reach to small to mid-size machine shops due to cost, space, or inaccurate perceptions about what it takes to adopt the technology. LPBF has been highly popular in industries like medical device and aerospace who are looking for highly complex metal geometries that may be difficult or near impossible to machine, for the benefit of weight reduction, component consolidation, efficiency, and reducing cost in low volumes of highly specialized parts.

The founders and engineers of Xact Metal saw an opportunity to create an easy to use, space-saving, and most importantly a low-cost point of entry into this capability with the XM200C. Driven by the patent-pending Xact Core™, a high-speed precision X-Y gantry system, as opposed to traditional galvanometer ones, that allows light and simple mirrors to move quickly, consistently, and always perpendicular to the powder bed to maintain accuracies down to .002”. The 125in³ volume is big enough to tackle large handheld parts, and Praxair delivers quality metal powders to build highly dense parts. In the recent past, most would expect to be into a quarter of a million dollars to have LPBF technology in house, where the Xact system all-in price starting at $140k, without sacrificing accuracy and reliability, reduces total cycle time by about 50% without the need for debind and sintering steps found in earlier low-cost 3D metal printing systems.

Cimquest views this addition of Xact Metal to our 3D printer line-up as a gateway for those customers who have been hungry to move out of using plastic prototypes. With this new affordable option, they can move to useable, weldable, complex components in stainless steels, super alloys, copper, and even aluminum and titanium if their facilities allow. This can meaningfully democratize the metal 3D printing space for so many more businesses that were out of reach of it, just a few years ago.

Cimquest opens new office in Cincinnati, Ohio

Loveland, Ohio, USA April, 9 2018

Cimquest Inc., a manufacturing solutions company based in Branchburg NJ, has taken their expertise to the Ohio region. The grand opening of their new Cincinnati Office and 3D Printing Showroom marks a major milestone in the company’s 28 year history.

Cimquest’s entrance into the Midwest gives manufacturers in the region access to a reputable source for the latest 3D printing and scanning technologies, including hardware, software and services. They represent industry leading 3D printing brands such as HP, Desktop Metal and Formlabs. Firms can schedule visits to the expansive showroom to see various machines in action.

While Cimquest offers direct product sales, they employ a unique consultative approach. When working with a new company, Cimquest will evaluate the company’s applications and help determine the best solutions that can accelerate the product development process (even if it is not one of their own solutions). Their knowledge of both additive and subtractive process can provide a unique perspective for companies looking to use traditional production methods like CNC machining in conjunction with the modern processes like large scale 3D printing.

View the Video Link of Grand Opening Recap Here

Cimquest Inc. was founded in 1990 and offers a comprehensive line of products and services for manufacturing and design. From software for CNC programming (Mastercam) to hardware for prototyping and production, they can equip companies (small and large) with the tools needed to bring ideas to life.

RIZE announces the XRize.

WOBURN, Mass., USA November 7, 2018

In a giant leap to deliver flexibility and scalability to customers, RIZE INC., a Boston, USA-based, next-generation additive manufacturing company, has announced new hardware, materials and IoT functionality: XRIZE™, the world’s first true color desktop industrial 3D printer, RIZIUM™ CARBON and RIZIUM™ ENDURA materials and the RIZE™ CONNECT cloud platform.

Until now, users had to produce non-functional color parts or implement very expensive solutions, making tradeoffs between color, strength and price. These tradeoffs have limited the expansion of additive manufacturing to users across the enterprise and inhibited true innovation. Moreover, companies had to purchase separate 3D printers to achieve varying capabilities, including office use, full color, end-use and production parts and the ability to use carbon fiber and other materials.

For the first time in the industry, XRIZE enables users to manufacture functional polymer and composite parts in full color. And since RIZE’s intelligent and innovative solutions focus on the user as much as the machine, XRIZE is easy to use, safe and enables markup to provide much-desired IP security, traceability and branding.

Like RIZE’s first product, RIZE™ ONE, the experience of using the XRIZE 3D printer is as easy and safe as an office 2D printer. Providing a safe, clean process, minimal pre- and post-processing and minimal material management, users throughout the enterprise, from engineering to marketing to the manufacturing floor, can use XRIZE to easily manufacture full-color prototypes for FEA and stress analysis, tooling with safety instructions, consumer products, package design, GIS mapping, anatomical parts for patient/clinician communication, pre-surgical planning and parts for marketing and the entertainment industry.

XRIZE leverages RIZE’s patented Augmented Deposition process by extruding an engineering-grade thermoplastic and simultaneously jetting C, M, Y, K (cyan, magenta, yellow and black) inks through industrial printheads to achieve the full-color part. RELEASE INK is jetted between the part and the automatically-generated supports to enable the user to quickly peel the supports away from the part, leaving a smooth surface finish and eliminating the need for additional finishing. With RIZE ONETOUCH software, users can quickly and easily apply text, images and texture maps to monochrome part files and import color CAD files.

Key Features:

• Full, CMYK color 3D printing with best-in-class Z-strength

• Runs multiple materials: RIZIUM ONE, RIZIUM BLACK and the new RIZIUM CARBON and RIZIUMENDURA materials

• Minimal pre- and post-processing provide the fastest time to part

• Easy to operate with an auto-leveling build plate, automatic filament changeover and intuitive

high-resolution touch screen for access to part library, build management and system

diagnostics

• Heated build chamber for industrial part strength and accuracy

• Safe process and materials for office compatibility

• Secure; Internet/Cloud connectivity optional

Key Specifications:

• Four-channel color and dedicated Release Ink channel

• Device dimensions: 21.4” H x 36” W x 25.4” D (535 x 915 x 647mm)

• Build volume: 12”x 8” x 8” (310 x 200 x 200mm)

• Weight: 135 lbs (61kg)

• Layer thickness: .250mm or .125mm

• Resolution: x/y 300dpi; Z 200dpi at .125mm layer thickness

• Accuracy: X/Y: +/- .127mm, or +/-.003mm/mm, whichever is greater and Z: +/- layer thickness

(.250mm or .125mm)

With an MSRP of $55K USD (and €55K Euro), XRIZE will be available in 2019.

RIZIUM™ CARBON Material

RIZIUM CARBON is an engineering-grade thermoplastic filament reinforced with carbon fiber for a

superior visual finish and higher modulus. RIZIUM CARBON is ideal for applications such as functional

prototyping for manufacturing.

RIZIUM™ ENDURA Material

RIZIUM ENDURA is a fiber-reinforced filament providing high-accuracy and high-impact strength. It is

ideal for large functional parts and is compatible with RIZE’s full-color inks.

RIZE CONNECT

RIZE CONNECT enables users to remotely manage and monitor their RIZE ONE and XRIZE 3D printers

from any location to improve production efficiency. Users can receive notifications, queue jobs and

manage an enterprise print farm from desktop and mobile devices. Using RIZE CONNECT, users can also

build greater security into their parts with digital part identification and other forms of part

augmentation, such as QR codes and version control for part traceability, compliance and authenticity.

RIZE CONNECT will be available in 2019.

“Our mission from the beginning has been inclusive and sustainable innovation,” said Andy Kalambi,

President and CEO of RIZE. “With this approach, we can take additive manufacturing anywhere and to

everyone. The way to do that is to make industrial 3D printing easy, safe and fully digital. Our innovative

platform approach is the core to driving sustainable innovation. With the launch of XRIZE, RIZIUM

CARBON, RIZIUM ENDURA and RIZE CONNECT, we are now realizing the potential of this platform,

providing our customers with maximum flexibility, complete ease of use and quickest ROI.”

RIZE will demonstrate its comprehensive suite of new and existing products November 13-16 at

Formnext in booth 3.1/C28. In addition, RIZE VP of Product, Kishore Boyalakuntla, will discuss this

announcement in detail during a presentation, RIZE: Announcing a Technology Platform for Connected

Innovation and Scale, on November 13, 2:45PM on the TCT Stage at Formnext.

About RIZE

RIZE is a Boston, USA-based company defining desktop additive manufacturing. RIZE’s first product,

RIZE™ ONE, won numerous industry and customer accolades. IDC named the Company a ‘2018

Innovator in 3D Printing Solutions’ and RIZE earned the 2018 Frost & Sullivan award for ‘Best Practices in

Technology Innovation in the Zero-Emission Polymer Material Additive Manufacturing industry.’

Prestigious organizations like NASA, US Army, US Navy and Merck have chosen the product for

supporting their additive manufacturing needs.

RIZE additive solutions combine simplicity, speed, safety, strength and security, all at the lowest cost of

ownership in the industry. For more information, visit www.rize3d.com.

Contact:

Julie Reece

Vice President of Marketing, RIZE Inc.

Julie.reece@rize3d.com

+1 978 699 3085 ext. 708

Cimquest Announces Partnership with Rize

Branchburg, NJ (October 12, 2017)

Cimquest has announced an agreement with Rize Inc. to sell and support the Rize 3D printing platform in the Mid-Atlantic and Northeast territories, encompassing the state of Virginia all the way through Maine. In addition to their current offerings of HP and Desktop Metal 3D printers, Cimquest can now offer the Rize™ One powered by the patented Augmented Polymer Deposition (APD) process.

“With so many new introductions of 3D Printers over the last several years failing to meet customers’ expectations, it is very refreshing to see how Rize has hit the mark in quality, reliability and performance with the new Rize One 3D Printer, said Rob Hassold, Founder and CEO of Cimquest. “With the unmatched ability to produce uniform part strength in a machine that is environmentally safe, we are seeing amazing interest from many business sectors such as: schools and universities as well as military applications in confined spaces.”

“We are delighted to partner with Cimquest.” said Rize Founder and resident, Eugene Giller. “As one of the leading additive manufacturing and CAD/CAM integrators in North America, Cimquest is ideally positioned to bring the unique material properties and process benefits of Rize’s patented, APD technology to its customer base.”

Suitable for a lab, office or field environment, Rize™ One is the only 3D printer that harnesses Rize’s patented Augmented Polymer Deposition (APD) platform. APD involves the simultaneous extrusion of Rize’s own compound of engineering- and medical-grade thermoplastic and jetting functional inks wherever they are needed to change the material properties of the thermoplastic at the voxel level. This enables users to jet Release One ink between the support material and the part for quick, easy, clean and safe support removal with their hands. This can be immediately followed by printing and Marking Ink, for 3D printing detailed text and images in and on parts. Rize parts are watertight and have isotropic strength, are twice as strong as ABSplus and even stronger than polycarbonate and carbon fiber-reinforced parts in the Z-axis. They have a high HDT, can be sterilized and provide chemical resistance to acid, acetone, alcohol and more. Moreover, the APD process and materials are safe and environmentally friendly and the printer itself is desktop size, so it can be used virtually anywhere for fast, easy and affordable production of replacement and custom tooling, fixtures, jigs and end-use parts.

Cimquest will demonstrate Rize APD technology and the Rize One 3D printer at next week’s Advanced Manufacturing Expo, where Eugene will also deliver a presentation, “The Challenges Additive Manufacturing Technologies Face in Achieving Isotropic Strength

###

Cimquest Now a Reseller of HP Multi Jet Fusion Technology

Branchburg, NJ (September 25, 2017)

Cimquest has announced an agreement with HP Inc. to sell and support HP Jet Fusion 3D printers in the Mid-Atlantic and Northeast territories, encompassing the state of Virginia all the way through Maine.

“I am excited to combine Cimquest’s award-winning customer service with HP’s award-winning 3D printing platform. Our 19 years of 3D printing and 28 years of subtractive manufacturing (Mastercam) experience coupled with HP’s true high volume production technology provides a unique solution to the market. No single manufacturing process stands alone and with our expertise with many manufacturing processes, Cimquest is well suited to support our customers’ selection and implementation of 3D printing.” Says Rob Hassold – Founder/CEO of Cimquest, Inc.

The HP Jet Fusion 3D 4200 solution offers an end-to-end platform for prototyping and production based on HP’s Multi Jet Fusion technology. This solution lowers the barriers of entry to additive manufacturing by providing faster build speeds, high-quality functional parts, and breakthrough economics. The HP Jet Fusion 3D 4200 machine operates through a unique Multi-Agent printing process, offering dimensional accuracy, fine aesthetics, and superior mechanical properties. Parts can currently be printed in High Reusability PA 12, but many new materials will be available down the line through HP’s Open Materials program. HP’s Open Materials program enables third-party companies to develop unique materials that are certified for HP Multi Jet Fusion, providing customers with an ever-growing portfolio of materials for different applications. Learn more about how the technology works here:

Interested parties are welcome to see the HP Jet Fusion printer at the Advanced Manufacturing Expo being held October 18th and 19th at Cimquest’s NJ headquarters, where more than 10 different 3D Printer manufacturers will be exhibiting. There will also be more than 25 unique technical seminars covering specific technologies and applications. To register and for further information go to https://cimquest-inc.com/2017ame/

About Cimquest, Inc.:

Cimquest, Inc. is a leading resource for 3D Printing, CAM, and Reverse Engineering solutions. They operate the largest 3D printing showroom in the Northeast and have been helping designers and manufacturers bring ideas to life for 27 years. Cimquest additionally provides rapid prototyping services, 3D scanning & inspection services, Mastercam training, manufacturing training, and technical support.

###

PD involves the simultaneous extrusion of Rize’s own compound of engineering- and medical-grade thermoplastic and jetting functional inks wherever they are needed to change the material properties of the thermoplastic at the voxel level. This enables users to jet Release One ink between the support material and the part for quick, easy, clean and safe support removal with their hands. This can be immediately followed by printing and Marking Ink, for 3D printing detailed text and images in and on parts. Rize parts are watertight and have isotropic strength, are twice as strong as ABSplus and even stronger than polycarbonate and carbon fiber-reinforced parts in the Z-axis. They have a high HDT, can be sterilized and provide chemical resistance to acid, acetone, alcohol and more. Moreover, the APD process and materials are safe and environmentally friendly and the printer itself is desktop size, so it can be used virtually anywhere for fast, easy and affordable production of replacement and custom tooling, fixtures, jigs and end-use parts.

Cimquest will demonstrate Rize APD technology and the Rize One 3D printer at next week’s Advanced Manufacturing Expo, where Eugene will also deliver a presentation, “The Challenges Additive Manufacturing Technologies Face in Achieving Isotropic Strength

###

Cimquest expands through the Addition of Fisher Unitech’s Mastercam Related Business

Branchburg, NJ – Last month, Cimquest, Inc, a leading provider of manufacturing products and services, announced the expansion of the company’s Mastercam business territory. As of August 16, 2017, Cimquest has taken over Fisher Unitech’s Mastercam business in Pennsylvania, Virginia, West Virginia… for Mastercam sales, support and services. The deal significantly expands Cimquest’s Mastercam customer base and sales territory, which now encompasses Virginia all the way through Maine.

Cimquest would like to welcome Brian Brown, Tony DiSanto, Chris Jepson, Andy Lowry, Todd Patterson, Jeff Reiser and Mike Steelman to their team. They are excited to have such a strong team of Mastercam experts to add to their world-class talent who together will offer unparalleled support, consulting and training services to the manufacturing community. With the addition of the Fisher Mastercam technical team, Cimquest will be the largest Mastercam support organization in the world!

“This is truly exciting times; with our expanded customer base and team of experts we are now going to be able to provide a complete range of solutions and services unmatched by any other CAD/CAM CNC support organization in the world. Look for more announcements about additional offerings from Cimquest such as CNC Programming services and Advanced Manufacturing training that goes well beyond the scope of Mastercam,” says Rob Hassold, CEO/Founder of Cimquest.

Mastercam President Meghan S. West stated “Cimquest has been a trusted and loyal reseller since 1990. We are both confident and pleased for the customers in their expanded territory. The level of service that Cimquest provides is at the top of the industry. Mastercam users are in exceptional hands and should look forward to a strong support network in this new territory”.

Additionally, Cimquest Stratasys customers will be supported by Fisher Unitech. Fisher Unitech will no longer be representing Mastercam and Cimquest will no longer be representing Stratasys. Although Cimquest will no longer be selling and supporting Stratasys products, they now have the opportunity to build a much more diversified 3D printer portfolio to better serve their customers’ needs. Cimquest will be announcing new 3D printing partnerships in plastic, metal and other materials in the near future.

About Mastercam

Mastercam NC programming software for 2-axis, 3-axis, simultaneous 4-axis & 5-axis milling, multi axis lathe, Mill-Turn, Wire EDM and routers. Founded in MA in 1983, CNC Software, Inc. is one of the oldest developers of PC-based computer-aided design / computer-aided manufacturing software. They are one of the first to introduce CAD/CAM software designed for both machinists and engineers. For more information, visit www.mastercam.com.

About Cimquest, Inc.:

Cimquest, Inc. is the leading resource for Mastercam, 3D printing solutions, and 3D scanning/inspection technology. Cimquest, Inc.’s headquarters and Advanced Manufacturing Showroom is located in Branchburg, NJ. To learn more about Cimquest, Inc.’s products, services, support and training offerings, visit www.cimquest-inc.com.

###

Cimquest Inc. signs contract to Re-sell Desktop Metal 3D Printing Systems

Branchburg, NJ, (May 15, 2017) Cimquest, the leading resource for Mastercam and 3D Printers is now contracted to sell Desktop Metal. This means that in addition to offering, Mastercam, 3D scanning and inspection, as well as traditional 3D printers, Cimquest can now offer the New England and Mid-Atlantic territories a Metal 3D Printer at a price point that will allow the manufacturing community to venture into the exciting field of 3D Metal Printing.

This will open up new opportunities for current Cimquest customers, from Maine to Maryland, and allow them to get into the metal 3D printing arena. Rob Hassold, CEO of Cimquest says, “I am excited that with Desktop Metal prototyping and production system technology we are the first reseller in the world to be able to leverage 19 years of additive manufacturing experience as well as over 27 years of subtractive (Mastercam) CNC programming technology to provide state-of-art manufacturing solutions for today’s industry leaders. With over 25 technical experts serving the additive and subtractive space we are well positioned to handle almost any challenge served by those technologies.”

Some of the benefits of this new Desktop Metal 3D printing system include:

- The Desktop Metal Studio System is 10 times less expensive than existing technology today.

- It eliminates the need for expensive, industrial facilities to safely house the technology.

- Makes metal 3D printing drop-dead simple.

- Significantly increases the versatility of prototyping.

The DM Studio System is available to reserve in May with shipping beginning in August 2017. The complete DM Studio System, including printer, debinder, and furnace, is $120,000. The DM Production System is available to reserve in May for shipping beginning in 2018.

Cimquest will be hosting a special webinar on May 19th at 9AM to present Desktop Metal’s unique and affordable metal printing process. Learn how the rules of traditional metal manufacturing solutions are changing with the advent of innovative approaches that reduce costs and significantly increase speed, safety, and print quality. Register online today to learn how Desktop Metal plans to reinvent the way engineering and manufacturing teams produce metal parts – from prototyping through mass production. Follow this link to register for this free webinar: http://info.cimquest-inc.com/desktop-metal

About Desktop Metal

Desktop Metal, Inc., based in Burlington, Massachusetts, is accelerating the transformation of manufacturing with end-to-end metal 3D printing solutions. Founded in 2015 by leaders in advanced manufacturing, metallurgy, and robotics, the company is addressing the unmet challenges of speed, cost, and quality to make metal 3D printing an essential tool for engineers and manufacturers around the world. For more information, visit www.desktopmetal.com.

Cimquest, Inc. Promotes Shawn Crews to Company President

BRANCHBURG, NJ (October 13, 2015) – Cimquest, Inc., manufacturing products and services provider, today announced the promotion of Shawn Crews to company President. He will have the primary responsibility of managing company operations.

“Cimquest has grown dramatically in the past several years and it became obvious that my role of President/CEO needed to be divided amongst myself and another key individual. Shawn has been a key part of our success, and we are thrilled to promote him to this important position. This change will allow Shawn to focus on the day-to-day operations while I concentrate on longer term objectives as well as working more closely with vendors, partners and various areas of the company that will benefit from my closer interaction” said Robert Hassold, CEO of Cimquest.

Mr. Crews received a Bachelor of Science in Mechanical Engineering degree from Lehigh University.

About Cimquest, Inc.:

Cimquest, Inc. is the largest Mastercam support organization in the United States and is the leading provider of Stratasys 3D Printers in the Northeast. In addition, Cimquest provides 3D printing and scanning services including the proprietary 3D IRIS scanning technology for First Articles. Cimquest, Inc.’s headquarters and Advanced Manufacturing Showroom is located in Branchburg, NJ with additional offices in Sterling, MA and Harrisburg, PA.

To learn more about Cimquest, Inc.’s products, services, support and training offerings, visit www.cimquest-inc.com.

###

For information contact:

Susan Gaffney, Cimquest, Inc., 866-277-8778 x240.