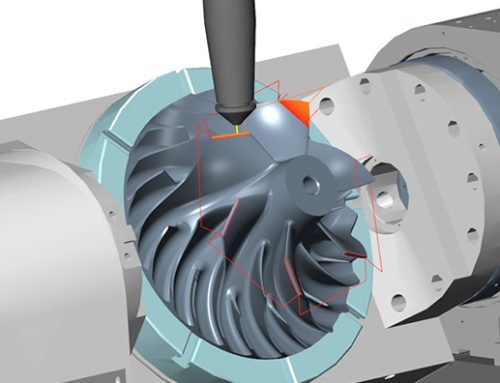

Mastercam’s Dynamic Motion Technology can shrink lead times and slash operating costs with constant chip load. This CAM roughing technology is designed to take full advantage of the latest cutting tool advancements. For more than a half-century, material scientists understood the theoretical benefits of a phenomenon known as RCT (Radial Chip Thinning). RCT has to do with the behavior of cutting tools when step-overs are 50% or less. As step-overs decrease, too wear decreases too, as long as the chip load remains constant. As step-overs are decreased, material removal rates must be increased to maintain constant chip loads and manage heat removal so that the cutting tool does not fail prematurely.

There are many paybacks to using this Dynamic Motion Technology and today we will cover just a couple . . .

Payback #1: Increase Cutting Tool Life

Cutting tools frequently represent a very high percentage of a manufacturing business’ operating expense. Dynamic Motion technology used at constant chip loads according to the manufacturers recommendations have resulted in up to 5x improvements in cutting tool life. In many shops, those savings would pay for one or more additional CNC machines.

#2 Reduce Machine Cycles

With Dynamic Motion technology, improved material removal rates go hand-in-hand with reduced cutting tool wear. With shallower step-overs but deeper step-downs, today’s advanced cutting tools will last longer, as they continually bite into enough material to carry the heat away from the cutting tool and the material. Based on what your machine can handle (and this is very easy to determine), you can progressively decrease step-overs and increase speeds until you arrive at the “sweet spot” where you have the best balance of material removal volume and tool life. Both will almost always be better than results on conventional aggressive hogging out strategies that rely on >50% step-overs and shallow depths of cut.

Please stay tuned for more Dynamic Motion Paybacks in future blog postings. And if you can’t wait and want to find out more right away, please contact us today!

Leave A Comment